Improving Rail Networks with Intelligent Maintenance

Maintenance was once referred to as the "necessary evil" , something to be done in order to check off boxes at periodic maintenance intervals, but kept to a minimum in the name of cost reduction and inconvenience. But in highly-legislative, safety-critical industries like rail, maintenance has always been integral to effective management of the network, keeping trains on schedule, and to reduce safety risk to both man and machine.

Today, the challenge of balancing performance, reliability, availability, maintainability, and safety with reduced budgets, human resource, and time, is increased. All of these priorities combined are essential in delivering profitable operations that are safe and effective across the rail operators network. How can you afford to compromise?

Rail operators are often challenged by reductions in budget and reduced workforce availability (headcount) to maintain standards and specifications. The introduction of predictive maintenance systems can simplify maintenance. This is of tremendous value to rail operators and managers who are tasked with obtaining the best value from their investment. Net increases of both safety and reliability are achieved, while providing the maintenance teams tools to assist in detecting and locating potentially damaging electrical faults quickly and accurately.

Engineers and asset managers know the importance of a good maintenance regime and how a planned intervention, performed at the right time using predictive maintenance, is the key to a successful, reliable railway, versus just hoping periodic maintenance finds something on a quarterly, semi-annual, or annual basis.

But how can this be achieved in less time, especially in a challenging trackside environment? The solution lies in remote condition monitoring.

What is Remote Condition Monitoring?

The days of sending engineers onto tracks, through rail traffic and hazardous terrain, are increasingly limited. Exposing workers and staff to the risks of the rail environment means working at the lowest level of the safety hierarchy.

With Bender's remote condition monitoring, networks can be monitored from a distance to provide status and advanced warning of an asset's condition. This increasing toolkit of data provides opportunities for new ways of working, analysis and risk reduction that were previously unachievable.

Benefits of Remote Condition Monitoring - Increased Rail availability/uptime, reduced time to diagnose, and increased work safety

Innovations in monitoring technology and remote condition monitoring have opened-up the possibility of better balancing the tensions that exist between the needs for minimal intervention and continuous improvement in workforce and passenger safety. Remote condition monitoring ensures:

- Advanced warning of asset condition

- Optimal asset performance and management

- Reduced system intervention/downtime

- Increased worker safety

- Increased passenger safety

- Increased reliability and availability of the network

Bender Remote Condition Monitoring

We have brought together the technology and systems to introduce new solutions for railway maintenance. Reducing the need for workers to be exposed to track conditions, preventing trackside accidents and improving electrical safety of rail networks can be achieved by enabling a reduction in both capital spending and operating expense costs for rail operators.

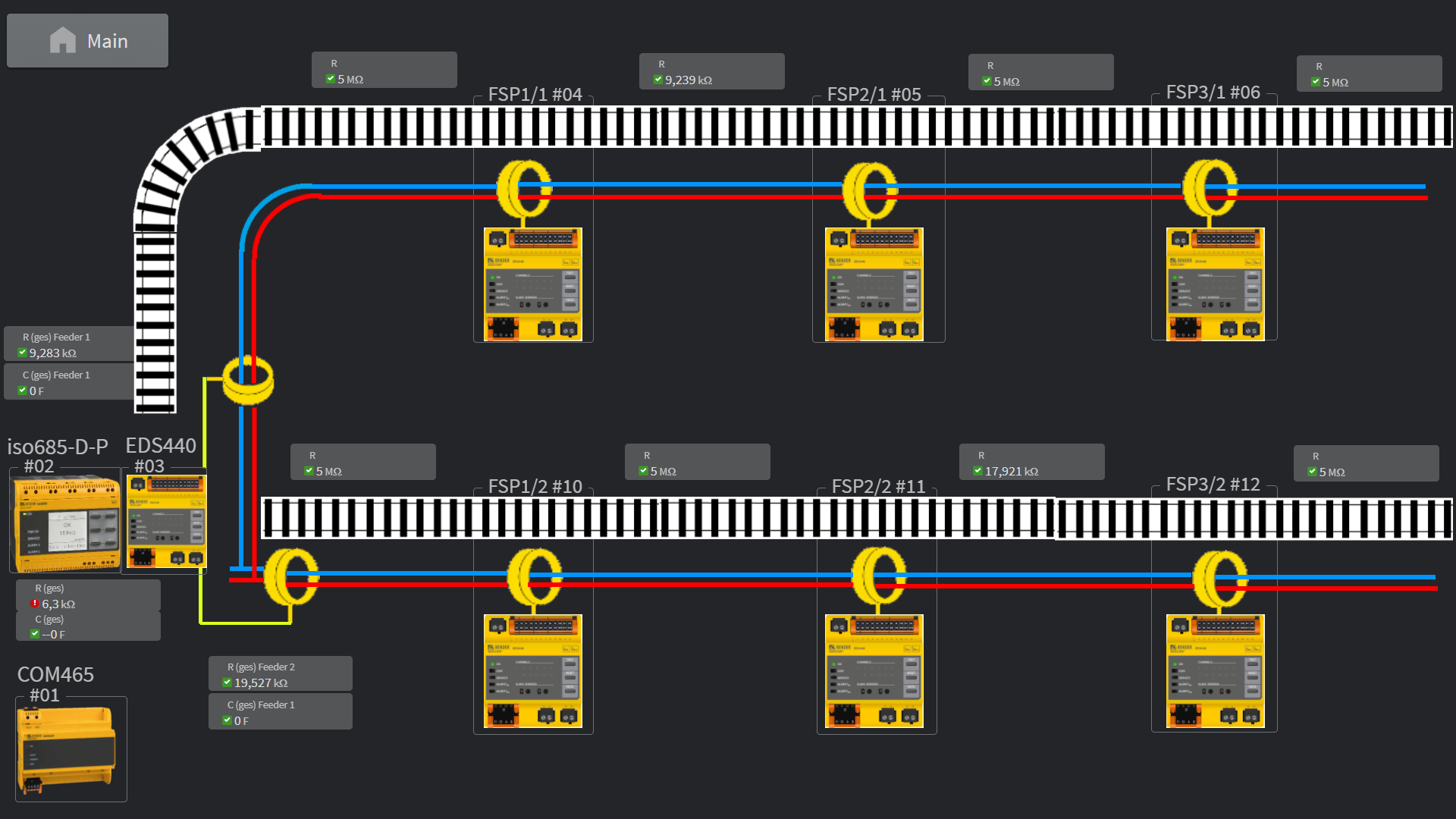

Bender's Insulation Monitoring and EDS Fault Location technology helps to manage trackside power distribution safely and effectively without having to access the track at all.

Management of damaged or faulty cables

Several key benefits are:

- Engineers can monitor cables during the build phase of a project.

- Maintenance teams can manage existing