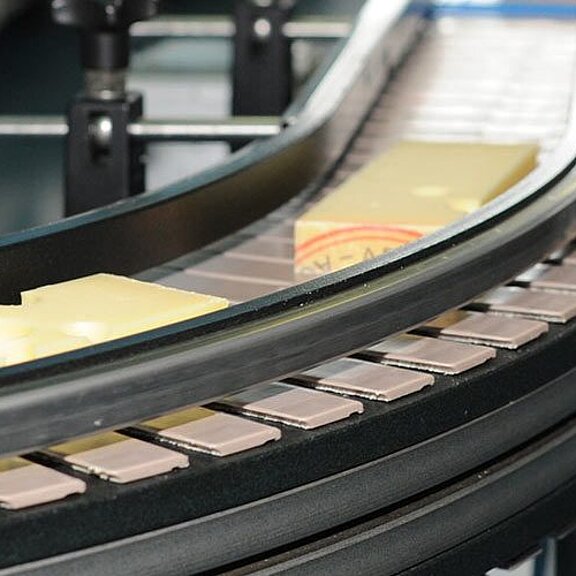

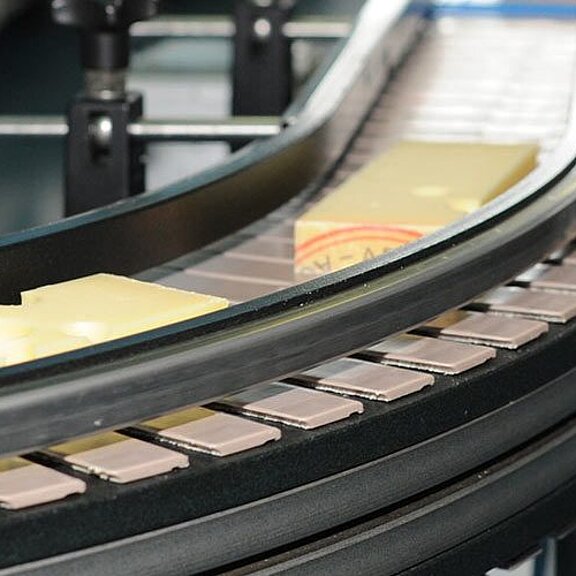

Paper mills have provided paper products for civilization for centuries. Historically, they have always been an early adapter of new technology. In the 20th century, paper mills worldwide began converting from hydro to electric power. With the adoption of electricity came an increased risk of fire due to the dust and paper break fibers, which a ground fault can easily ignite.

The process from the wood yard to the final product is often spread over a large area, making locating faults on these systems time-consuming and difficult. Interruption to the paper machines that produce large rolls of product at high speed is expensive and undesirable. Any unplanned interruption, whether from drive or control circuit trips, can have a painful impact on operations. Bender's ground-fault protection equipment provides advanced personnel, equipment, and fire protection to pulp and paper manufacturing. Quickly identify, trend, and locate ground faults to minimize manufacturing downtime and troubleshooting costs. Communication options allow for integration into existing Fieldbus networks, such as Modbus. By integrating Insulation Monitoring devices and transformer neutral grounding, Bender contributes to robust protection and fault detection throughout the entire manufacturing process.

Modern systems often employ variable frequency drives (VFDs), also called adjustable speed drives (ASDs), requiring special consideration to be adequately protected. These AC/DC loads are best protected by devices capable of monitoring their entire operating frequency range to capture AC and DC ground faults. Bender‘s ground-fault monitoring systems provide this advanced level of protection and can be included in turnkey ground-fault packages. For more information on Bender solutions in the pulp, paper, and packaging industry, read through our blogs on the topic.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| 2020 Guidelines (US) | Technical Information | 1.9 MB | EN | 2020/06/1515.06.2020 | |

| Overview Brochure | Product Overviews | 10.3 MB | EN | 2023/10/0202.10.2023 | |

| Pulp, Paper, and Forest Industries | Flyers | 1.9 MB | US | 2024/06/2020.06.2024 | |

| Bender Industry Applications | Market Segment Brochures | 5.9 MB | EN | 2024/09/0404.09.2024 |

Products

AC/DC ground-fault monitor

![[Translate to North American English:] RCM420 RCM420](/fileadmin/_processed_/5/3/csm_RCM420_01_WEB_70dba9c027.jpg)

AC ground-fault monitor

Multi-channel AC/DC ground-fault monitor

Multi-channel AC/DC ground-fault monitor with individual relay outputs

![[Translate to North American English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

Monitor for use in high-resistance grounded systems

![[Translate to North American English:] COMTRAXX® COM465IP](/fileadmin/_processed_/f/d/csm_COM465IP_01_WEB_296d1e7f5c.jpg)

Condition Monitor with an integrated gateway for the connection of Bender devices to Ethernet-TCP/IP networks

AC/DC ground-fault monitor

![[Translate to North American English:] RCM420 RCM420](/fileadmin/_processed_/5/3/csm_RCM420_01_WEB_70dba9c027.jpg)

AC ground-fault monitor

Multi-channel AC/DC ground-fault monitor

Multi-channel AC/DC ground-fault monitor with individual relay outputs

![[Translate to North American English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

Monitor for use in high-resistance grounded systems

![[Translate to North American English:] COMTRAXX® COM465IP](/fileadmin/_processed_/f/d/csm_COM465IP_01_WEB_296d1e7f5c.jpg)

Condition Monitor with an integrated gateway for the connection of Bender devices to Ethernet-TCP/IP networks