Ground-Fault Detection in Small Modular Reactor (SMR) and Fusion Applications

As the nuclear industry evolves toward advanced reactor technologies, electrical safety and monitoring systems must evolve alongside it. Ground-fault detection plays a vital role in ensuring system reliability and operator safety in small modular reactors (SMRs) and emerging fusion facilities, where complex electrical architectures and high-energy systems demand continuous, intelligent monitoring.

Understanding SMR and Advanced Reactor Designs

The Nuclear Regulatory Commission (NRC) refers to non-light water reactor (non-LWR) designs and small modular light water reactors (SMRs) collectively as advanced reactors. These designs incorporate innovative technologies compared to conventional fission reactors, including passive safety features, modular scalability, and alternative fuel or coolant types.

While non-LWRs employ distinct materials and coolants such as liquid metal or molten salt, SMRs represent a subset of light-water reactors engineered to be more compact, factory-assembled, and deployable in distributed configurations. Many SMR designs emphasize passive safety systems and simplified electrical architectures that minimize operator intervention while maximizing resilience and uptime.

Fusion Energy and Its Electrical Challenges

Nuclear fusion is the process in which two atomic nuclei combine to form a heavier nucleus, releasing large amounts of energy. This is the same process that powers the sun and stars. Unlike nuclear fission, which splits atoms and produces long-lived radioactive waste, fusion produces minimal waste and no risk of runaway reactions, making it a promising clean-energy alternative.

To replicate the extreme conditions of fusion (temperatures exceeding 100 million degrees Celsius) technologies such as tokamaks and stellarators use powerful magnetic fields or high-energy lasers to confine hydrogen isotopes until fusion occurs. These systems rely on massive electrical power infrastructure, including medium-voltage (MV) power circuits, radio frequency (RF) heating systems, and superconducting magnet arrays, all of which require precise control and comprehensive ground-fault protection.

While fusion machines are often called "reactors," they differ from conventional fission reactors in that they do not sustain a self-propagating chain reaction. Instead, fusion devices require a continuous external energy input to maintain plasma confinement—meaning any electrical fault, insulation breakdown, or system instability could interrupt operation or damage critical equipment.

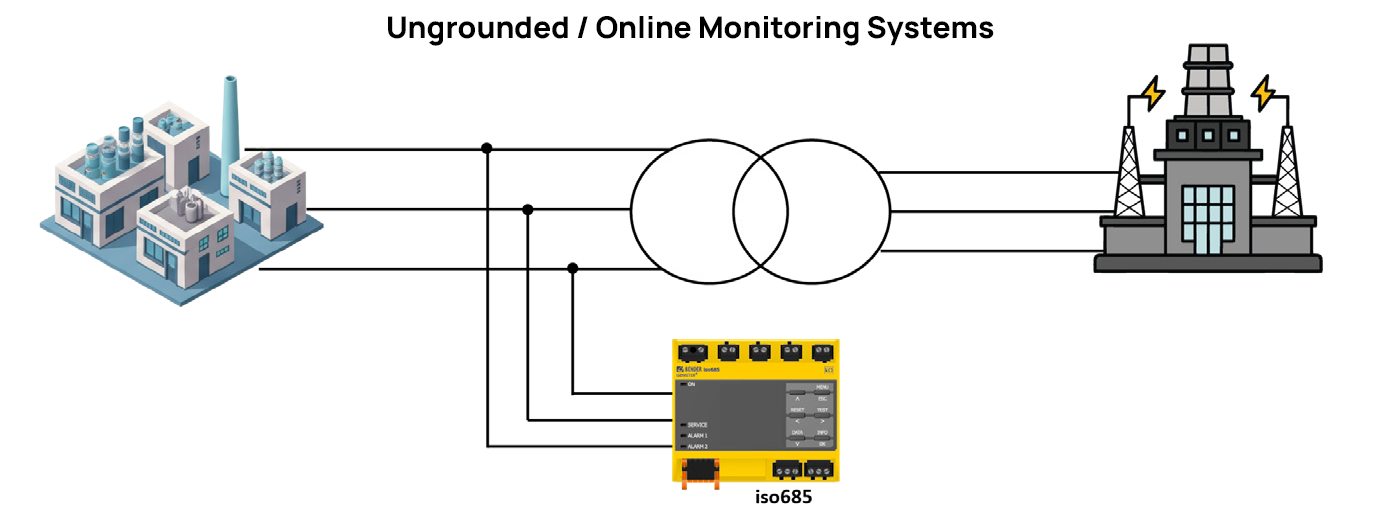

Bender insulation monitoring devices (IMDs) can monitor resistance to ground for energized ungrounded systems or monitor for ground faults on de-energized grounded systems. See grounded/offline monitoring systems below.

Enables ground-fault detection and displays localized ground-fault leakage current for any faults downstream of the current sensor. Using CTUB-CTBC current sensors allow some devices to monitor across a wide frequency band- where other devices are blind. Bender devices can be used on the AC power distribution and on the relay control power systems (typically 125 VDC battery systems).

Addition of an IMD on the load-side of feeder breakers provides the look-ahead function, also referred to as lockout protection. This provides system health information and prevention of energizing a faulted system.

Ground-Fault Detection Requirements in Fusion and SMR Power Systems

The high electrical loads that power fusion magnets and SMR auxiliary systems demand robust predictive monitoring and advanced insulation fault detection. In these applications:

Medium-voltage power circuits are often operated in an ungrounded (IT) configuration prior to energization, allowing engineers to detect insulation degradation before faults become critical.

These circuits are “offline monitored” using Insulation Monitoring Devices (IMDs) to verify insulation integrity prior to start-up.

Communication and control networks, which are essential for synchronizing plasma control and diagnostics, must also be monitored to ensure no ground faults or leakage currents introduce noise or disrupt signal integrity.

Once the power system transitions to an operational grounded state, the system’s residual current monitors (RCMs) continuously supervise the return paths to detect leakage or fault currents during live operation. This combination of IMDs and RCMs ensures full lifecycle protection - from pre-energization to steady-state operation.

Bender Solutions for Advanced Reactor Safety

Bender has developed a comprehensive portfolio of Insulation Monitoring Devices (IMDs) and Residual Current Monitoring (RCM) systems specifically suited to SMR and fusion applications. These systems are designed for medium-voltage environments, complex power architectures, and mission-critical uptime.

Bender’s ISOMETER® iso685 Series and EDS440 Series (Earth Fault Location) systems have been widely deployed across global fission plants, providing continuous fault detection, fault localization, and predictive maintenance data that minimize downtime. In advanced reactor environments, these same technologies are now being adapted for use in modular, transportable, and high-voltage power platforms.

By integrating real-time ground-fault detection and localization, operators can shorten response times, prevent unplanned outages, and protect both personnel and mission-critical assets. This predictive approach supports regulatory compliance, improves asset reliability, and aligns with the nuclear industry’s commitment to safety, efficiency, and continuous improvement.

Conclusion

As SMR and fusion projects move from concept to deployment, electrical safety will remain a defining factor in operational success. Ground-fault detection was once considered a post-incident diagnostic, but has become a predictive, data-driven discipline central to reactor safety and reliability. Bender’s advanced monitoring systems provide the intelligence and precision required to meet this next generation of nuclear energy challenges head-on.

At Bender Inc., we’ve been at the forefront of electrical safety for over 80 years. Our commitment to innovation and excellence drives us to create solutions that exceed expectations. When it comes to protecting your facility, trust the experts—trust Bender.

For more information about this application or to learn more about Bender technology related to your specific application, contact our team of experts.

This article is for informational purposes only. Bender provides the information "as is" without warranty and is not responsible for its accuracy or reliability. No warranties are given regarding its suitability for any specific circumstances.