The large crucibles and vats used in smelting systems are often moved by electric motors with various voltages and currents. Reliable, uninterrupted power is required to prevent the molten metal from solidifying in these containers. The power supply or transformer grounding is often designed ungrounded or resistance grounded. In refining systems, Neutral Grounding Resistor configurations are crucial for managing fault currents and protecting sensitive equipment from potential damage, thereby enhancing system reliability and safety. Bender fault location systems are available for resistance grounded and ungrounded systems to quickly and automatically locate defective power circuits. When using permanent insulation monitoring and insulation fault location systems, the cost of maintaining plants is considerably reduced, and the availability and safety of both plant and personnel are increased significantly.

The power supply is critical to refining and smelting systems. The medium voltage supplied to the facility is transformed down to 480 V or 600 V and distributed through the facility via electrical cables or busbars, often referred to as branch feeders. It is then either connected to loads or transformed to lower voltages. Depending on the system grounding, either a Bender ISOMETER®s or RCMS residual current monitoring relays (ground-fault monitors) monitor these and help ensure continuous operation. Fault detection is only the first step in troubleshooting. Adding downstream monitors and current sensors can allow for quicker and safer location of ground faults. References mention that approximately 80-95% of the faults in a facility start as a phase-to-ground fault - making this time savings compound the return of investment.

Continuity of Service

Control fault current and have alarm-only operation on the first ground-fault.

Ease of Retrofit

Ability to easily and cost-effectively upgrade older equipment.

Improved Safety

Reduces potential for shock and arc flash hazard. Arc flash is reduced by as much as 95%. Automatic fault location at feeders and loads can eliminate the need to open doors on energized equipment during troubleshooting.

Reduces Maintenance Costs

Accuracy of detection leads to a decrease in maintenance costs and the need for human interaction with the system.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| 2020 Guidelines (US) | Technical Information | 1.9 MB | EN | 2020/06/1515.06.2020 | |

| Overview Brochure | Product Overviews | 10.3 MB | EN | 2023/10/0202.10.2023 | |

| Mining | Market Segment Brochures | 3.8 MB | EN | 2024/09/0404.09.2024 | |

| Electrical Safety in a Modern Nickel Smelting Plant | Technical Article | 358.8 KB | EN | 2019/05/1313.05.2019 | |

| Bender Industry Applications | Market Segment Brochures | 5.9 MB | EN | 2024/09/0404.09.2024 |

Products

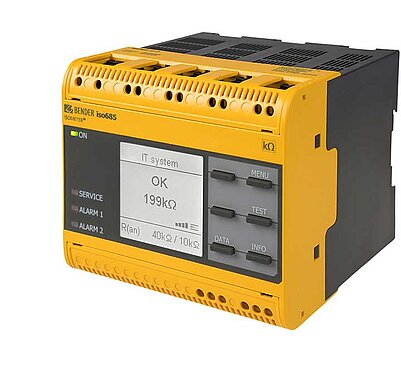

Ground-fault detector for ungrounded AC/DC systems

![[Translate to North American English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

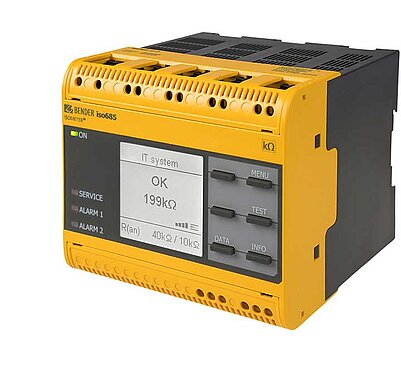

Monitor for use in high-resistance grounded systems

Ground-fault detector for ungrounded AC/DC systems

![[Translate to North American English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

Monitor for use in high-resistance grounded systems